Solutions for Enhancing Concentricity

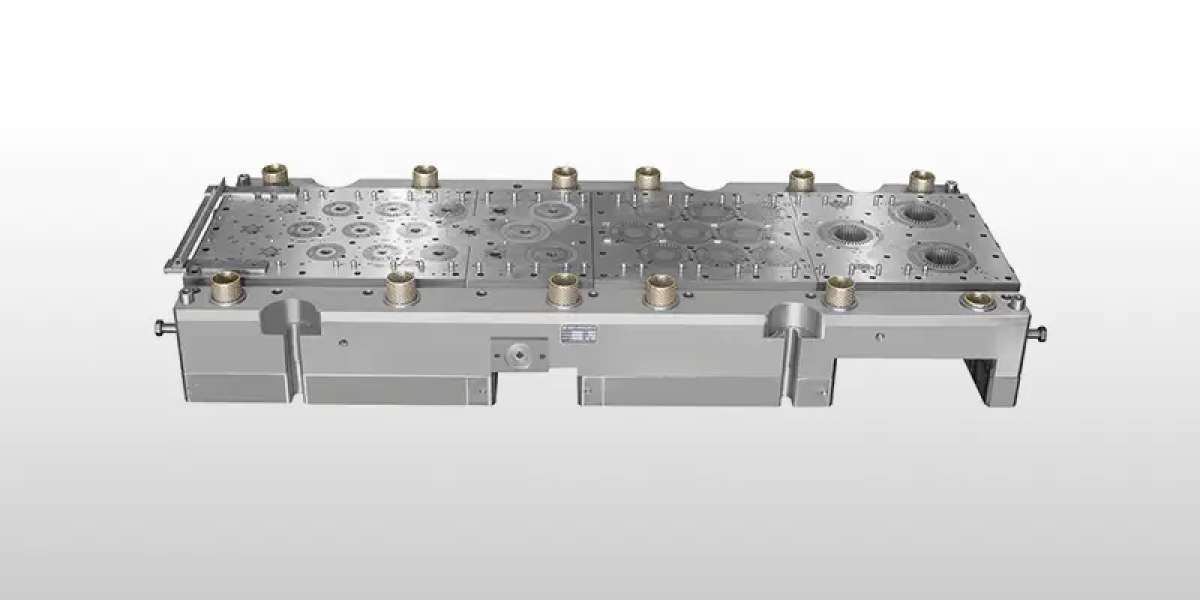

1. Advanced Manufacturing Techniques: Implementing advanced manufacturing techniques, such as computer numerical control (CNC) machining, can significantly improve the precision of rotor core stampings(https://www.motorcoremold.com/product/high-speed-punch-progressive-stamping-die/). These techniques allow for tighter tolerances and more consistent production quality, reducing the likelihood of concentricity issues.

2. Material Selection and Quality Control: Careful selection of materials with uniform properties and rigorous quality control measures can help ensure that the components meet the necessary specifications. Conducting thorough inspections and tests on incoming materials can prevent issues from arising later in the manufacturing process.

3. Tooling Maintenance: Regular maintenance and monitoring of stamping tools and dies are essential to maintaining precision. Implementing predictive maintenance schedules and using high-quality materials for tooling can extend their lifespan and improve the consistency of the produced components.

Suche

Beliebte Beiträge

-

Nghệ Nhân Nguyễn Xuân Hà Hồi Sinh Cây Mai Vàng Trở Thành Tác Phẩm Nghệ Thuật Độc Đáo

Durch phocohanoi2

Nghệ Nhân Nguyễn Xuân Hà Hồi Sinh Cây Mai Vàng Trở Thành Tác Phẩm Nghệ Thuật Độc Đáo

Durch phocohanoi2 -

Busty Escorts in Hong Kong: A Glimpse into a Unique Service Industry

Durch Jenny Hui

Busty Escorts in Hong Kong: A Glimpse into a Unique Service Industry

Durch Jenny Hui -

What's The Point Of Nobody Caring About Slot Volatility

Durch rainbet3027

What's The Point Of Nobody Caring About Slot Volatility

Durch rainbet3027 -

The Little-Known Benefits To Basic Mobility Scooters

Durch mymobilityscooters5227

The Little-Known Benefits To Basic Mobility Scooters

Durch mymobilityscooters5227 -

Giới thiệu Cách Chăm Sóc Hoa Mai Nở Đúng Tết

Durch nguyenbich

Giới thiệu Cách Chăm Sóc Hoa Mai Nở Đúng Tết

Durch nguyenbich

Kategorien