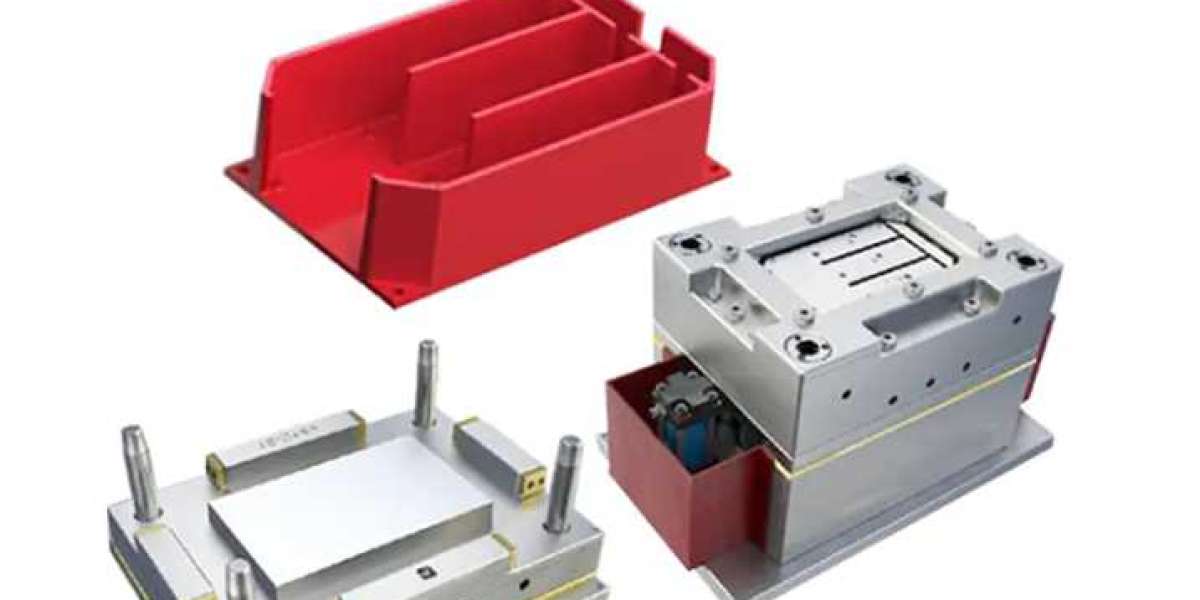

The BMC Mould is essential for producing high-strength and durable composite parts using Bulk Molding Compound (BMC) materials. This molding process involves applying heat and pressure to BMC material, allowing it to flow into the mold cavity and take on the precise shape of the design. The result is a component with excellent strength and dimensional stability, making BMC moulds ideal for creating complex shapes and intricate details. From automotive components to electrical enclosures, these molds enable the efficient production of parts that meet the exacting demands of various industries.

The precision and durability of BMC moulds are achieved by using high-quality materials such as steel or aluminum, which can withstand the extreme conditions of the molding process. This makes BMC moulds a reliable choice for industries requiring components that are both lightweight and durable. Learn more about the capabilities and applications of BMC moulds at BMC Mould.

Applications of BMC Moulds in Industry

BMC moulds are widely used across industries including automotive, construction, and electrical manufacturing. Their ability to produce components with intricate details and complex shapes allows manufacturers to create customized solutions that cater to specific needs. For instance, BMC Manhole Cover Moulds are often used in infrastructure projects, offering a lightweight yet strong solution for manhole covers and frames. In the electrical sector, SMC Circuit Breaker Box Moulds enable the production of reliable and durable enclosures for sensitive equipment.

The versatility of BMC moulds is further demonstrated in industrial equipment and automotive components, where strength and precision are critical. By enabling mass production of these essential components, BMC moulds support the development of modern infrastructure and technology. Discover more about the broad range of applications of BMC moulds by visiting BMC Mould.