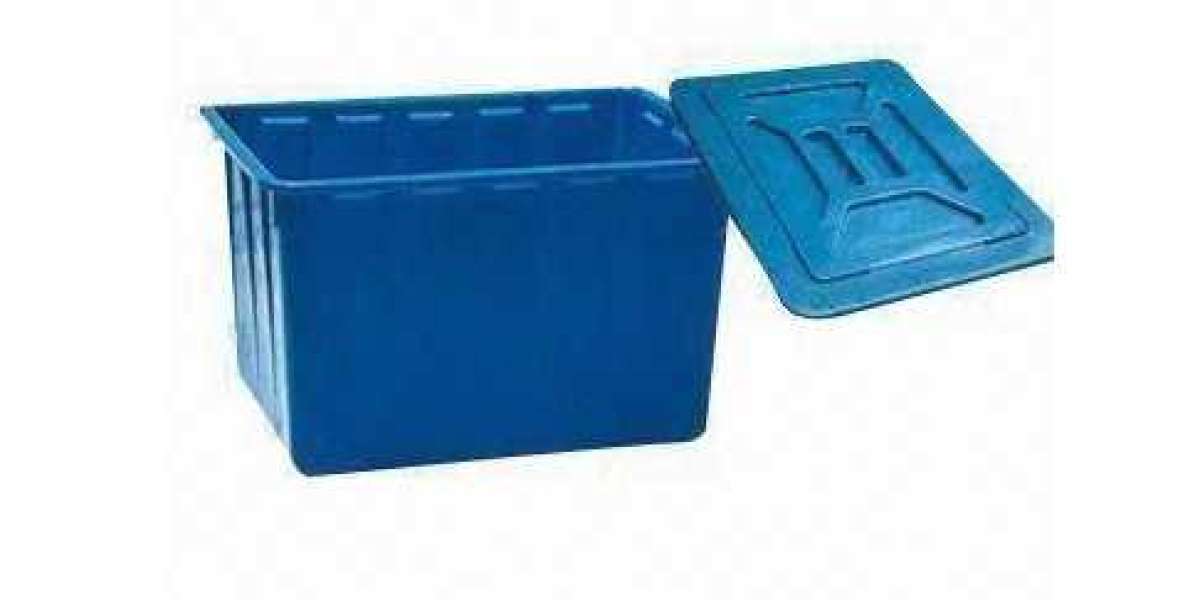

Plastic box moulds have become a cornerstone in various industries, offering a versatile solution for diverse applications. These moulds, characterized by their adaptability and efficiency, play a crucial role in manufacturing processes across sectors such as packaging, automotive, electronics, and consumer goods. With their ability to produce high-quality plastic boxes of different shapes and sizes, plastic box moulds have established themselves as indispensable tools in modern manufacturing.

One of the primary functions of plastic box moulds is to facilitate the production of plastic boxes used for packaging purposes. In industries ranging from food and beverage to pharmaceuticals, these moulds enable the mass production of containers that are essential for storing and transporting products safely. The precise design and construction of the moulds ensure consistency in the dimensions and quality of the plastic boxes, meeting the stringent requirements of the packaging industry.

Moreover, plastic box moulds find extensive applications in the automotive sector. From storage compartments to protective casings, plastic boxes are integral components of vehicle interiors and exteriors. The flexibility offered by moulds allows manufacturers to customize the design of these boxes according to specific automotive requirements, ensuring excellent fit and functionality. Whether it's organizing tools in the trunk or housing electronic components under the hood, plastic boxes manufactured using moulds contribute to the efficiency and durability of automobiles.

In the realm of electronics, plastic box moulds play a pivotal role in the production of housing enclosures for electronic devices. With the ever-increasing demand for gadgets and appliances, there is a constant need for high-quality plastic enclosures that offer protection and aesthetics. Plastic box moulds enable manufacturers to produce enclosures that are not only durable and resistant to environmental factors but also aesthetically pleasing. Whether it's a sleek smartphone casing or a rugged outdoor camera housing, the versatility of plastic box moulds ensures that they can cater to a wide range of electronic applications.

Furthermore, the consumer goods industry benefits significantly from the versatility of plastic box moulds. From storage containers to display stands, plastic boxes serve various purposes in retail and household settings. The ability to produce boxes in different colors, designs, and sizes allows manufacturers to cater to diverse consumer preferences and market trends. Whether it's organizing household items or showcasing retail products, plastic boxes manufactured using moulds provide a practical and visually appealing solution for consumers.

The widespread adoption of plastic box moulds can also be attributed to their cost-effectiveness and efficiency in production. Compared to traditional manufacturing methods, such as injection molding, plastic box moulding offers a more streamlined and economical approach. The ability to create multiple cavities within a single mould reduces production time and material wastage, leading to cost savings for manufacturers.

In conclusion, plastic box moulds represent a versatile and indispensable solution for a wide range of applications across various industries. From packaging and automotive to electronics and consumer goods, these moulds play a crucial role in manufacturing processes, enabling the production of high-quality plastic boxes that meet diverse requirements. As industries continue to evolve, the versatility and adaptability of plastic box moulds will ensure their continued relevance and importance in manufacturing processes worldwide.