Lightweight and Cost-Effective: One of the primary advantages of 28mm PET preform is their lightweight nature. Compared to glass or aluminum, PET significantly reduces shipping costs and overall packaging weight, making it a more economical choice for manufacturers.

Recyclability: PET is one of the most widely recycled plastics, making 28mm PET preforms an environmentally friendly option. Consumers are increasingly looking for sustainable packaging solutions, and using recyclable materials can enhance a brand's appeal.

Enhanced Product Protection: The barrier properties of PET provide excellent protection for beverages, maintaining their flavor and carbonation. This advantage is crucial for soft drinks, juices, and other beverages that require long shelf life and quality preservation.

Ease of Manufacturing: The production process for PET preforms is efficient and straightforward. They can be produced rapidly using injection molding, which allows manufacturers to meet high demand without compromising quality.

Versatility: The 28mm neck finish is compatible with various applications, from bottled water to sports drinks. This versatility means that companies can use the same preform design for multiple products, simplifying their inventory and production processes.

Compatibility with Automated Systems: Many bottling lines are designed to work with PET preforms, allowing for seamless integration into existing manufacturing processes. This compatibility helps manufacturers to automate their production lines, increasing efficiency and reducing labor costs.

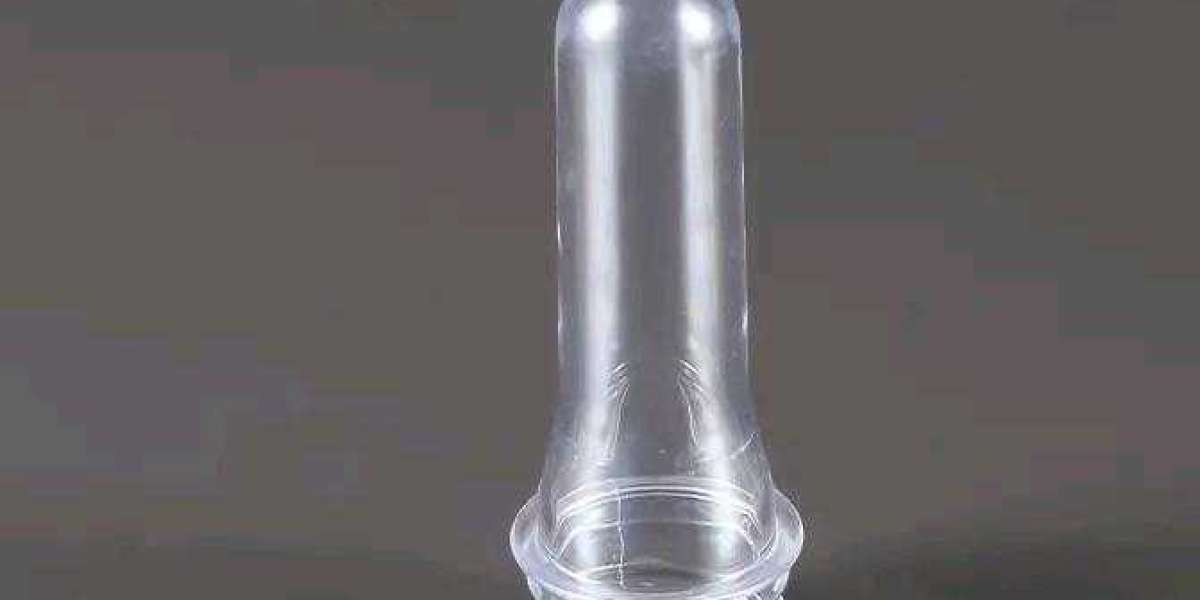

Aesthetic Appeal: The clarity and smooth finish of PET preforms make them visually appealing to consumers. A well-designed PET bottle can enhance product visibility on store shelves, positively impacting sales.

Reduced Carbon Footprint: By choosing lightweight materials like PET, manufacturers can reduce the carbon footprint associated with transportation. This reduction is increasingly important as companies strive to meet sustainability goals.