In the context of water treatment and management, the performance of Paddle Aerators Suppliers under high-temperature conditions is a critical factor to consider. Paddle Aerators Suppliers are integral to the process of maintaining water quality, and their equipment's ability to function effectively in extreme heat is paramount. The question of how these suppliers' paddle aerators perform in high-temperature environments is not just a matter of operational efficiency but also of environmental sustainability.

Paddle Aerators Suppliers are well aware of the challenges that high temperatures can pose to their equipment. The heat can affect the mechanical components, leading to increased wear and tear, and can also impact the biological processes that the aerators are designed to support. To address these concerns, Paddle Aerators Suppliers invest in research and development to ensure that their products are not only durable but also efficient in extreme conditions.

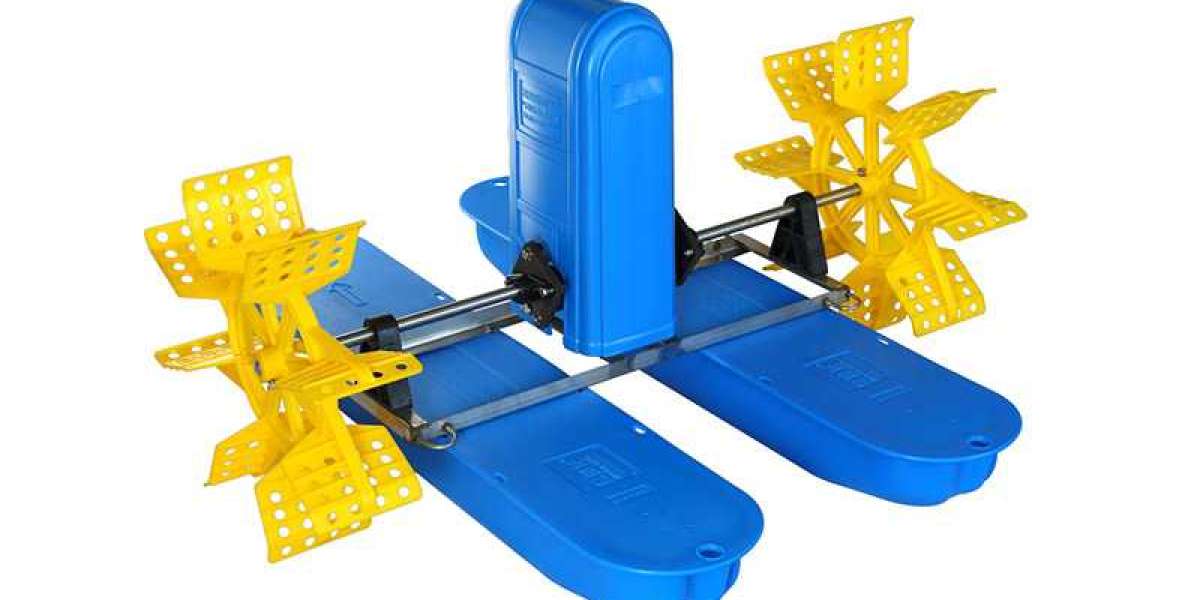

One of the key aspects of Paddle Aerators Suppliers' performance in high-temperature environments is the material used in the construction of their aerators. High-quality, heat-resistant materials are essential to withstand thermal stress without compromising the structural integrity of the equipment. Paddle Aerators Suppliers are committed to using such materials, which not only ensures the longevity of their products but also maintains their efficiency in delivering oxygen to the water.

Another critical factor is the design of the paddle aerators. Paddle Aerators Suppliers employ innovative designs that maximize the surface area for oxygen exchange, even in conditions where the solubility of oxygen in water is reduced due to high temperatures. This design consideration is crucial for maintaining the health of aquatic life and preventing the proliferation of anaerobic bacteria, which can lead to water quality degradation.

The operational efficiency of Paddle Aerators Suppliers' equipment in high-temperature environments is also a testament to their engineering prowess. The aerators are designed to minimize energy consumption while maintaining optimal oxygen transfer rates. This balance is crucial, as high temperatures can lead to increased energy demands. Paddle Aerators Suppliers are at the forefront of developing energy-efficient solutions that can perform reliably even under the most demanding conditions.

Maintenance is another area where Paddle Aerators Suppliers excel. They provide comprehensive maintenance schedules and protocols that are tailored to the specific needs of their clients. This proactive approach to maintenance helps to ensure that the aerators are always in top condition, ready to perform at their best even in high-temperature scenarios.

In conclusion, the performance of Paddle aerator suppliers in high-temperature environments is a complex interplay of material science, engineering design, and proactive maintenance. These suppliers are dedicated to providing solutions that not only meet the immediate needs of their clients but also contribute to long-term environmental sustainability. By investing in research, using high-quality materials, and focusing on energy efficiency, Paddle Aerators Suppliers can deliver aeration systems that perform reliably and effectively, even in the face of extreme heat. This commitment to excellence ensures that Paddle Aerators Suppliers remain a trusted partner in the ongoing quest for clean and healthy water bodies worldwide.