If you are looking for reliable solutions for producing high-quality plastic cups, explore the Plastic Cup Mould to streamline your manufacturing process.

Key Applications of the Plastic Cup Mould Series

The Disposable Plastic Cup Mould Series is designed for creating lightweight and durable disposable cups and lids. These molds are ideal for beverage applications, offering reliable sealing performance to prevent leaks and spills. The molds are precision-engineered to ensure consistency, making them a valuable asset for manufacturers seeking dependable production tools.

With the ability to produce thin-walled cups, these molds strike a balance between lightweight design and structural strength. This makes them suitable for a wide range of liquid products, ensuring consumer safety and ease of use.

Features of the Disposable Plastic Cup Mould Series

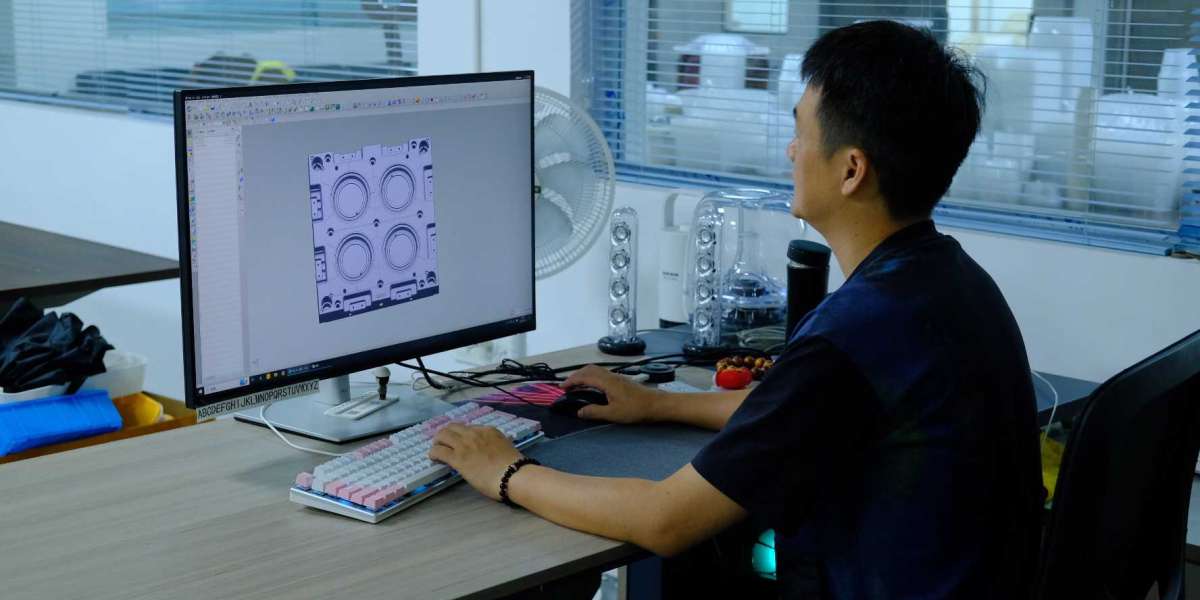

Precision in Manufacturing The Mould For Plastic Cup ensures dimensional accuracy, allowing manufacturers to produce cups and lids that adhere to exact specifications. High precision reduces material waste and ensures consistent product quality across production cycles.

Short Molding Cycle Efficiency is at the core of this product. With a molding cycle of just 6-8 seconds, these molds enable manufacturers to achieve higher productivity while minimizing energy consumption. This not only saves time but also reduces operational costs.

Versatile Material Compatibility Designed to accommodate various materials such as polypropylene (PP) and polystyrene, the Disposable Plastic Cup Mould Series offers manufacturers flexibility in material selection. This adaptability ensures that the molds can meet diverse production requirements.

Advantages of Thin-Walled Plastic Injection Molding

Thin-walled plastic injection molds are a key feature of this series, allowing for the production of lightweight and durable products. The use of thin-walled technology minimizes material usage, leading to cost savings and environmental benefits. At the same time, the structural integrity of the cups remains uncompromised, making them easy to handle and transport.

Why Precision Matters in Plastic Cup Moulds

Consistency is critical in the production of disposable cups, especially when it comes to sealing performance. The Disposable Plastic Cup Mould Series is crafted with a focus on creating leak-proof and secure lids and cups. This enhances consumer trust while ensuring that the products are safe and suitable for liquid storage.

Furthermore, the precision in mold design reduces the need for frequent adjustments, saving manufacturers time and resources. The result is a seamless production process that consistently delivers quality products.

Tailored Solutions for Unique Manufacturing Needs

The Disposable Plastic Cup Mould Series also offers customization options, allowing manufacturers to adapt the molds to their specific production requirements. Whether it’s adjusting dimensions or incorporating unique design features, these molds provide the flexibility needed to meet diverse industry demands.

If your manufacturing process demands precision and adaptability, consider exploring the advantages of the Mould For Plastic Cup for your production line.