At this time, a great number of international businessmen have proposed increasingly stringent requirements for the production of precision molds. The mold parting surfaces that are provided by mold manufacturers are not allowed to be marked by manual polishing. This limitation is a requirement. A great number of domestic manufacturers are unable to fulfill this requirement. This requirement ought to be satisfied by general intermediate molds, which are of a size that falls between small and medium a356 Aluminum Alloy. When it comes to testing the design level, equipment level, process level, management level, quality assurance system, and personnel quality of the mold manufacturer, this requirement is one of the comprehensive indicators that are required.

The so-called test of precision mold design level includes determining whether or not the rationality of the design and the simplification of optimization are at their highest possible levels. There is still a significant amount of variation among Chinese mold makers. The testing of equipment level refers to the process of determining whether or not you have regular CNC equipment and whether or not you are processing it using the appropriate procedure. Currently, China is home to the most cutting-edge zinc die casting manufacturer equipment that can be found anywhere in the world. Mold manufacturing companies in China are fairly well equipped with all of the necessary tools. A quality assurance system and management level are both included. Increasing numbers of businesses are coming to the realization that they are of great significance.

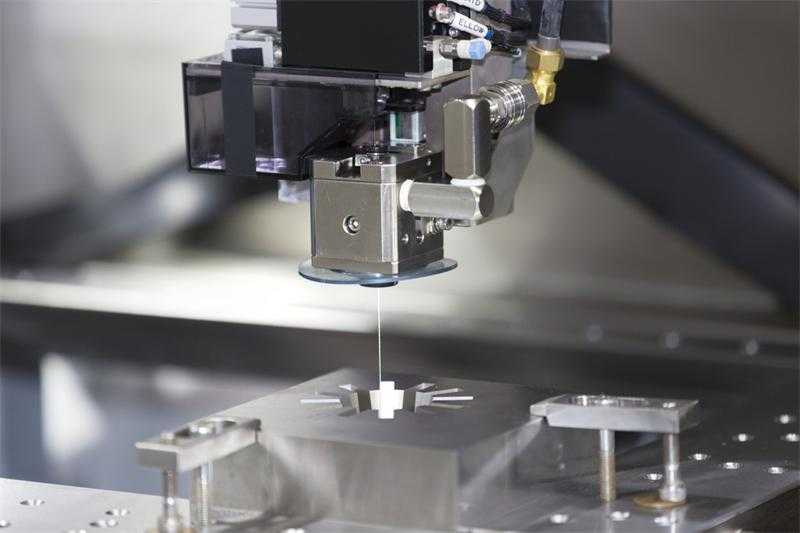

To begin, the optimal result is achieved by finishing the processing of mold parts three to four hours after the processing has been completed. Secondly, in order to minimize the amount of deformation that occurs during the processing of mold parts, it is necessary to find a solution to the problem of deformation that is caused by internal stress incurred during the entire process. During the process of cutting mold parts, the internal stress of the material that is being processed continues to accumulate. This is because of the changes that occur in cutting tools, electrodes, cutting wires, cold and heat, and fastening tools that exert force on the material. The cumulative effect makes an effort to alleviate the stress that is experienced on the inside. technique. The material stiffness is overcome and the shape of the workpiece changes, which ultimately results in deformation. This occurs when the accumulated internal stress reaches a certain level.

In the course of the cutting process, the material that is being processed will invariably accumulate internal stress, which will invariably result in the mold parts becoming deformed. Deep hole drilling, grinding, rough machining, electrical machining, and welding are the processes that cause the greatest accumulation of internal stress in mold parts. This is something that we are all common knowledge about. It is necessary to overcome the deformation that is brought about by the internal force of precision mold parts. The elimination of internal stress and mechanical reprocessing, or the combination of the two, are the two methods that can be utilized.

The application of heat therapy, which is what we typically refer to as stress relief, is typically used to alleviate the effects of internal stress. After being placed in the furnace, the steel is typically heated to a temperature of 590 degrees Celsius over the course of six to twelve hours, after which it is kept warm for two to six hours (depending on the size and thickness of the workpiece, as well as the local seasonal temperature), and finally it is cooled in the furnace. This procedure typically takes between twenty-four lost foam casting and forty-eight hours to complete. In general, aluminum components are placed inside the furnace, where they are heated to a temperature of 290 degrees Celsius over the course of six hours, maintained at a warm temperature for two to four hours (depending on the size and thickness of the workpiece, as well as the temperature of the local season), and then cooled inside the furnace. This process typically takes a full day to complete.

When machining, particularly rough machining, it is essential that the force exerted on the tool used for fastening is consistent. Multiple, diagonal methods of fastening, loosening, and tightening are typically utilized in most situations. Our standard procedure for processing involves locating a datum plane, which is a plane that does not change anything from the beginning to the end of the processing process, and then using that plane as a datum to process other components. Because of the accumulation of internal stress that occurs during the machining process, the datum plane also undergoes deformation. This deformation is caused by the machining process. When the datum is deformed, it can result in a wide variety of changes to other shapes. The trimming process brings about a great deal of change during the assembly process, which, when taken together, has a cumulative impact on the mold's quality and lifespan.

In order to ensure that the performance of precision molds is in accordance with the design requirements, it is necessary to find a solution to the common problem of overcoming deformation that is brought on by internal stress during the manufacturing process of molds. When rough machining, we typically choose several surfaces in different directions to serve as observation surfaces. This allows us to self-detect the degree of three-dimensional deformation that occurs during the working process. It is possible to attach it and then remove it during the finishing process if there is no ready-made one available. Because of this, the additional observation surface must not be too small; otherwise, the observation will be inaccurate. The idea is to make it as large as possible while simplifying the process of removing it. As an illustration, when it comes to a component lost foam casting that has a three-dimensional dimension of 1000×800×300mm, it is most commonly recommended to establish the length of the observation surface to be at least 900mm, 600mm, or 260mm. When the observation surface is smaller, the amount of error that exists between the value that was measured and the actual value is also greater.

In general, the value that is measured will be different from the actual length by one to two times if the length of the observation surface is only fifty zinc die casting manufacturer percent of the length of the actual workpiece.

After rough machining has been completed, after measuring the conditions of each observation surface and recording the data, you should attempt to completely loosen the fastening tool, but you should not change the position of the workpiece on the work surface. After that, you should measure the actual data of each observation a356 Aluminum Alloy surface of the workpiece, and then compare the two phases. In general, you will be able to determine the deformation of the workpiece that is being processed.

During the secondary tightening process, each fastening tool should be tightened once more until it does not move while being processed. Which is the most difficult. After that, perform a small amount of cutting on each observation surface until it is able to correctly play the role of the second datum in the correct manner. After turning the workpiece over:When trimming the original datum surface, the workpiece needs to be padded flat in order to comply with the deformation data that was measured after rough machining. In the event that the processing is carried out without padding, the shape of other components will be offset, which will lead to excessive cutting in certain components, no cutting at all in certain components, or even negative concavity. The purpose of this processing is to prevent the datum plane from becoming deformed, which will allow it to continue to serve as the first datum plane.