The China Cone Crusher, a pivotal piece of machinery in the mining and construction industries, is renowned for its ability to crush a wide range of materials. Its efficiency in processing different hardness of ores is a topic of significant interest for those in the field of mineral processing. This article delves into the intricacies of how the China Cone Crusher performs when faced with ores of varying hardness, examining the factors that influence its efficiency and the technological advancements that have been made to optimize its performance.

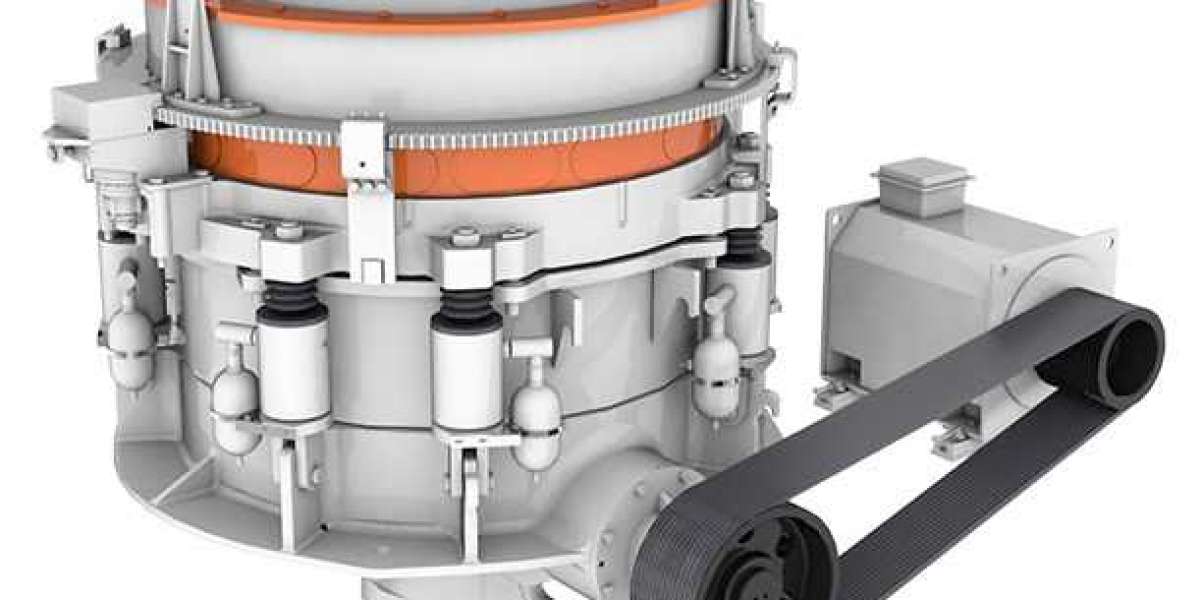

The China Cone Crusher operates on the principle of compressive crushing, where the ore is crushed between a fixed bowl liner and a moving mantle. The efficiency of this process is influenced by several factors, including the hardness of the ore, the size of the feed material, the speed of the crusher, and the setting of the discharge opening. When processing hard ores, the China Cone Crusher must exert more force to achieve the desired reduction in size, which can lead to higher energy consumption and potential wear on the crusher's components.

In the case of softer ores, the China Cone Crusher can achieve higher throughput rates with less energy expenditure. However, the crusher must be carefully adjusted to prevent over-crushing, which can lead to the production of excessive fines and reduced efficiency. The design of the China Cone Crusher, with its hydraulic adjustment system, allows for precise control over the closed side setting, ensuring that the crusher can be optimally configured for the specific hardness of the ore being processed.

The efficiency of the China Cone Crusher is also affected by the quality of the ore feed. The uneven or lumpy feed can lead to inefficient crushing and increased wear on the crusher's components. To mitigate this, many China Cone Crushers are equipped with pre-screening systems that remove fines and oversized material before it enters the crusher, ensuring a more consistent feed size and improving overall efficiency.

Advancements in technology have played a significant role in enhancing the efficiency of the China Cone Crusher. Modern crushers are often equipped with advanced monitoring systems that provide real-time data on the crusher's performance. This data can be used to make informed adjustments to the crusher's settings, optimizing its efficiency for the specific conditions it is operating under. Additionally, the use of wear-resistant materials in the construction of the China Cone Crusher's wear parts has extended the life of these components, reducing downtime for maintenance and contributing to increased efficiency over time.

Environmental considerations also play a role in the efficiency of the China Cone Crusher. The crusher's design must take into account the need to minimize dust and noise pollution, which can be achieved through the use of enclosed structures and noise reduction technologies. By addressing these environmental concerns, the China Cone Crusher can operate more efficiently without compromising the surrounding environment.

In conclusion, the efficiency of the China Cone Crusher in processing ores of different hardness is a complex interplay of design, technology, and operational practices. By understanding the factors that influence its performance and implementing strategies to optimize these factors, the China Cone Crusher can be a highly efficient tool in the mining and construction industries. As technology continues to advance, it is expected that the efficiency of the China Cone Crusher will continue to improve, making it an even more valuable asset in the processing of ores of varying hardness.