Welding approach:

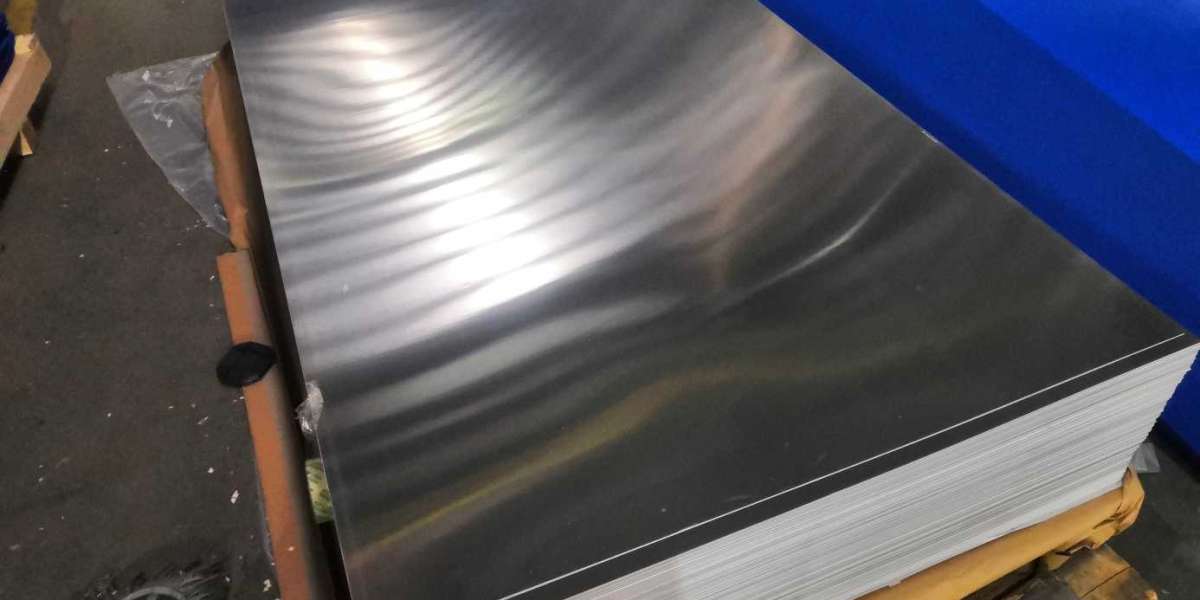

Nearly all styles of welding methods may be used for welding aluminum and aluminum alloys, aluminum and aluminum alloy however with distinct adaptability to a variety of welding strategies, diverse welding techniques have their respective programs. Gasoline welding and arc welding methods, gadgets, simple and easy to function. Welding can be used for much less stressful welding first-rate 3003 aluminum sheet and castings welding. SMAW welding aluminum alloy castings can be used. Inert gasoline welding approach is the maximum widely used approach for welding aluminum and aluminum alloys. Aluminum and aluminum alloy sheet can be tungsten or tungsten AC TIG pulse welding. Aluminum and aluminum alloy plate can use tungsten arc welding helium, argon-helium combined gas tungsten arc welding, MIG welding, pulsed MIG welding. MIG welding, pulsed MIG welding is extensively carried out, earlier than welding practise.(3003 h14 aluminum)

Smooth up earlier than welding:

1, aluminum and aluminum alloy welding, welding have to be strictly eliminated earlier than oxide movie and the oil and the workpiece weld wire surface; smooth up after such long time storage, reprocessing.(aluminum floor plate sale)

2, plate: aluminum at low temperature energy, correct go with the flow residences of liquid aluminum weld steel throughout welding prone to staying phenomenon. Which will make sure penetration but will not collapse, welding often used to maintain the plate and around the metallic tub. Pad may be graphite plate, chrome steel, carbon metal, copper, or copper and so on. Floor of the pad to open a circular grooves, in an effort to ensure that the weld terrible shape. Might not add facet welding plate forming, welding operation however calls for skilled arc welding or take strict energy automatic comments manipulate and different superior technological measures.

3, preheat: thin, small portions of aluminum usually do no longer preheat thickness 10 mm ~ 15mm preheat time may be, depending at the sort of aluminum alloy preheating temperature may be one hundred ℃ ~ 200 ℃, to be had oxygen a acetylene flame, furnace or other heating blowtorch. Preheat weldment can reduce distortion, reduce porosity and different defects. After the welding procedure.(aluminum alloy 5052)

Live clean up after welding and seam welding in the place of the residual flux and welding slag will damage the aluminum floor passivation movie, now and again corrode aluminum parts, must be wiped clean. Easy shape, the overall requirements of the workpiece may be a easy way with warm water or steam blowing scouring brush to clean. Traumatic and complex shape of aluminum elements in warm water after brushing with a stiff brush, and then at approximately 60 ℃ ~ eighty ℃, awareness of 2% to 3% aqueous answer of chromic acid or potassium dichromate answer immersion 5min ~ 10 min, and scrub with a stiff brush, then washed in hot water washing, drying oven or with warm air drying, can also be dried obviously.

Put up weld warmth remedy of aluminum boxes usually do no longer require publish-weld warmth treatment.

Sök

populära inlägg

-

Nghệ Nhân Nguyễn Xuân Hà Hồi Sinh Cây Mai Vàng Trở Thành Tác Phẩm Nghệ Thuật Độc Đáo

Förbi phocohanoi2

Nghệ Nhân Nguyễn Xuân Hà Hồi Sinh Cây Mai Vàng Trở Thành Tác Phẩm Nghệ Thuật Độc Đáo

Förbi phocohanoi2 -

Busty Escorts in Hong Kong: A Glimpse into a Unique Service Industry

Förbi Jenny Hui

Busty Escorts in Hong Kong: A Glimpse into a Unique Service Industry

Förbi Jenny Hui -

What's The Point Of Nobody Caring About Slot Volatility

Förbi rainbet3027

What's The Point Of Nobody Caring About Slot Volatility

Förbi rainbet3027 -

The Little-Known Benefits To Basic Mobility Scooters

Förbi mymobilityscooters5227

The Little-Known Benefits To Basic Mobility Scooters

Förbi mymobilityscooters5227 -

Giới thiệu Cách Chăm Sóc Hoa Mai Nở Đúng Tết

Förbi nguyenbich

Giới thiệu Cách Chăm Sóc Hoa Mai Nở Đúng Tết

Förbi nguyenbich