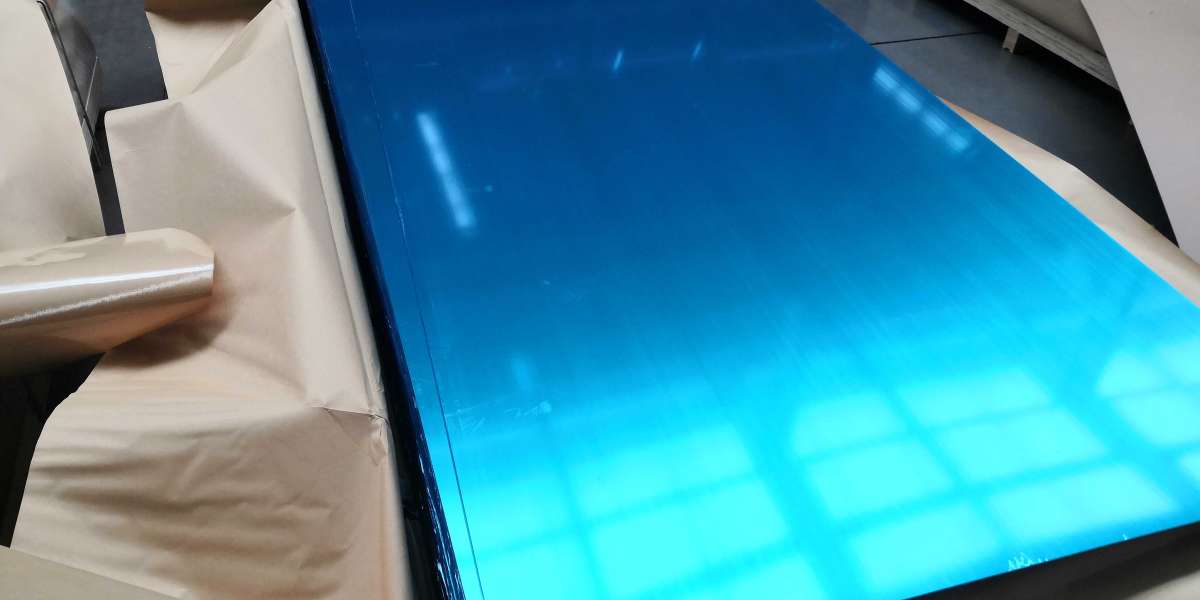

7075 aluminum sheet plate is a high-strength, high-hardness aluminum alloy plate1. It is known for its excellent mechanical properties, corrosion resistance, and wear resistance.

Composition and Manufacturing Process

7075 aluminum alloy’s composition roughly includes 5.6–6.1% zinc, 2.1–2.5% magnesium, 1.2–1.6% copper, and less than a half percent of silicon, iron, manganese, titanium, chromium, and other metals. The unique composition and production process contribute to its high strength and hardness.

Properties and Applications

7075 aluminum sheet plate is one of the highest strength aluminum alloys available. It has good machinability and an excellent strength-to-weight ratio. It is widely used in applications where strength is extremely critical.

This alloy is often used for highly stressed parts. It is more susceptible to embrittlement than many other aluminum alloys because of micro segregation, but has significantly better corrosion resistance than the 2000 alloys. It is one of the most commonly used aluminum alloys for highly stressed structural applications, and has been extensively utilized in aircraft structural parts.

Physical and Mechanical Properties

7075 aluminum sheet plate exhibits good ductility, high strength, toughness, and good resistance to fatigue. It has a density of 2,810 kg/m3 and a melting point of 532°C. The thermal expansion from 20°C to 100°C is 23.4 x10-6 /K, and the modulus of elasticity is 72.4 GPa. The thermal conductivity (Temper T6) is 130 W·m-1·K-1, and the electrical resistivity (Temper T6) is 0.0522 x10-6 Ω.m.

Conclusion

7075 aluminum sheet plate is a versatile material with a wide range of applications due to its unique properties. It offers a high degree of strength, ease of fabrication, and durability, making it an excellent choice for various industries, including aerospace, automobiles, construction, and electronic products

Search

Popular Posts

-

Nghệ Nhân Nguyễn Xuân Hà Hồi Sinh Cây Mai Vàng Trở Thành Tác Phẩm Nghệ Thuật Độc Đáo

By phocohanoi2

Nghệ Nhân Nguyễn Xuân Hà Hồi Sinh Cây Mai Vàng Trở Thành Tác Phẩm Nghệ Thuật Độc Đáo

By phocohanoi2 -

Busty Escorts in Hong Kong: A Glimpse into a Unique Service Industry

By Jenny Hui

Busty Escorts in Hong Kong: A Glimpse into a Unique Service Industry

By Jenny Hui -

What's The Point Of Nobody Caring About Slot Volatility

By rainbet3027

What's The Point Of Nobody Caring About Slot Volatility

By rainbet3027 -

The Little-Known Benefits To Basic Mobility Scooters

The Little-Known Benefits To Basic Mobility Scooters

-

Giới thiệu Cách Chăm Sóc Hoa Mai Nở Đúng Tết

By nguyenbich

Giới thiệu Cách Chăm Sóc Hoa Mai Nở Đúng Tết

By nguyenbich