In a world where convenience and efficiency are highly valued, the manufacturing industry constantly seeks innovative solutions to streamline production processes. One such indispensable component in the beverage industry is the cap mould company. A well-designed bottle cap ensures product freshness, prevents leakage, and promotes ease of use. Behind every reliable bottle cap lies the pivotal role of a bottle cap mold, which plays a crucial role in shaping and creating these essential closures.

Function and Importance of Bottle Cap Molds:

A bottle cap mold serves as a fundamental tool in the manufacturing process of bottle caps. It is responsible for shaping molten materials such as plastic or metal into the desired form, ensuring consistency, accuracy, and durability. The function of a bottle cap mold goes beyond mere aesthetics; it ensures the proper seal to maintain product quality, prevents contamination, and the integrity of the beverage.

The Process of Bottle Cap Mold Manufacturing:

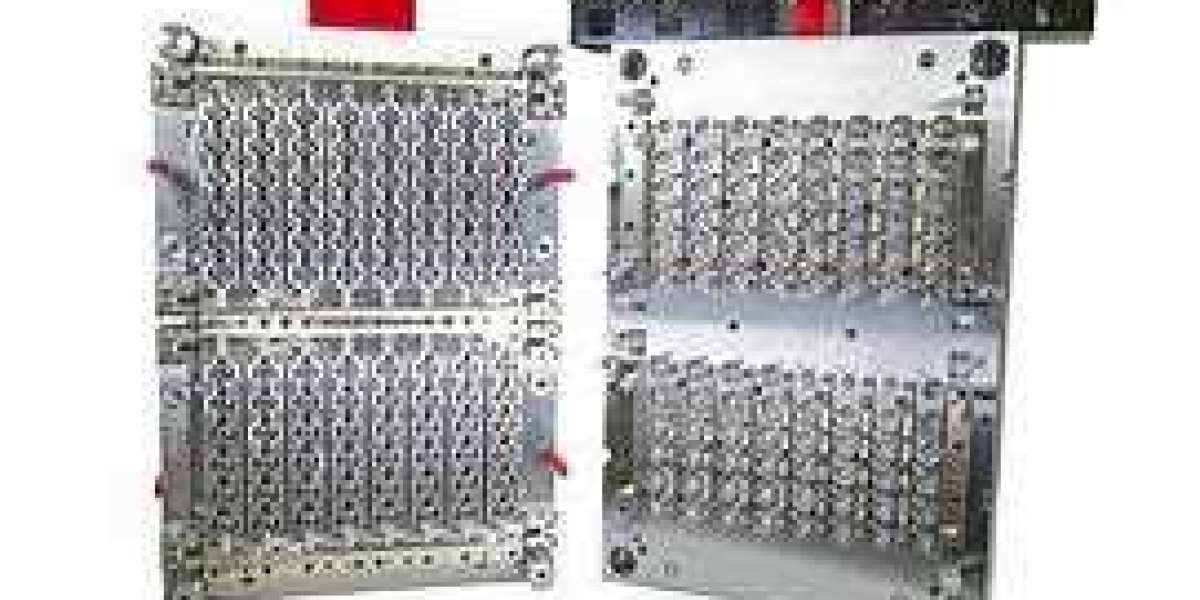

The creation of a bottle cap mold involves a meticulous process that combines engineering precision and craftsmanship. To begin, a detailed design of the desired bottle cap is created, taking into account factors such as size, shape, functionality, and brand specifications. This design serves as a blueprint for the mold-making process.

Next, a mold maker utilizes advanced techniques and tools to construct the mold. The mold is typically made from high-quality materials such as stainless steel or aluminum, chosen for their durability and heat resistance. The mold makerfully carves out the cavities and contours required for the final bottle cap product. This intricate process demands precision and expertise to ensure that the resulting mold will produce high-quality bottle caps consistently.

Once the mold is complete, it goes through rigorous testing and quality control measures. These ensure that the mold is capable of delivering consistent results, meeting specifications, and adhering to industry standards. Any necessary adjustments or modifications are made to guarantee the great fit and function of the bottle cap mold.

Applications and Adaptability of Bottle Cap Molds:

Bottle cap molds find applications in a wide array of industries, including beverages, pharmaceuticals, cosmetics, and food products. Their adaptability spans different types of bottles such as water bottles, soda bottles, juice bottles, and more. The versatility of bottle cap molds allows manufacturers to meet the diverse demands of the market efficiently.

Moreover, bottle cap molds can be customized to accommodate branding requirements and important designs. This flexibility ensures that companies can create bottle caps that not only provide practical functionality but also serve as a vehicle for brand identity and recognition. With the assistance of bottle cap molds, companies can effortlessly mold their brand image on every product, further enhancing brand loyalty and customer satisfaction.

Quality and Efficiency Enhancements:

The use of a well-designed and properly functioning bottle cap mold brings numerous advantages to the manufacturing process. It enables the production of consistent, high-quality bottle caps at a faster rate, meeting market demands efficiently. This enhanced efficiency minimizes production time, allowing manufacturers to meet and optimize their operations.

Furthermore, a precise bottle cap mold ensures a great seal, reducing the risk of leakage and preserving the freshness and quality of the beverage. This not only contributes to customer satisfaction, but also prevents financial losses associated with product spoilage or customer complaints.

Environmental Impact and Sustainability:

In recent years, there has been growing concern regarding the environmental impact of single-use plastics, including bottle caps. Manufacturers are under pressure to adopt sustainable practices and reduce waste. Bottle cap molds play a crucial role in this pursuit by enabling the production of recyclable and eco-friendly bottle caps. Responsible material choices combined with efficient molding techniques contribute to reducing the overall environmental footprintConclusion:

The bottle cap mold serves as a vital component in the manufacturing process, shaping bottle caps that ensure product freshness, prevent leakage, and promote convenience. With their functionality, adaptability, and quality enhancements, bottle cap molds enable manufacturers to meet market demands effectively. As the industry continues to evolve, bottle cap mold technology will undoubtedly play an essential role in driving efficiency, sustainability, and customer satisfaction in the ever-growing beverage market.