Using a low voltage servo motor offers several advantages over higher voltage alternatives, making it a preferred choice for many applications. Firstly, low voltage servo motors typically consume less power, resulting in reduced energy costs and environmental impact. This energy efficiency is particularly advantageous in applications where continuous operation is required, such as in manufacturing processes or robotics.

In terms of performance, low voltage servo motors can deliver comparable or even superior results to standard voltage servo motors. Despite operating at lower voltages, advancements in motor design and control technology have enabled low voltage servo motors to achieve high levels of precision, speed, and torque output. This enhanced performance ensures that low voltage servo motors can meet the demanding requirements of various industrial and automation applications.

When selecting a low voltage servo motor for a specific application, several factors must be considered to ensure optimal performance and reliability. One crucial factor is the power requirements of the application, including the desired speed and torque output. It's essential to choose a low voltage servo motor with sufficient power capabilities to meet these requirements while operating within its voltage range.

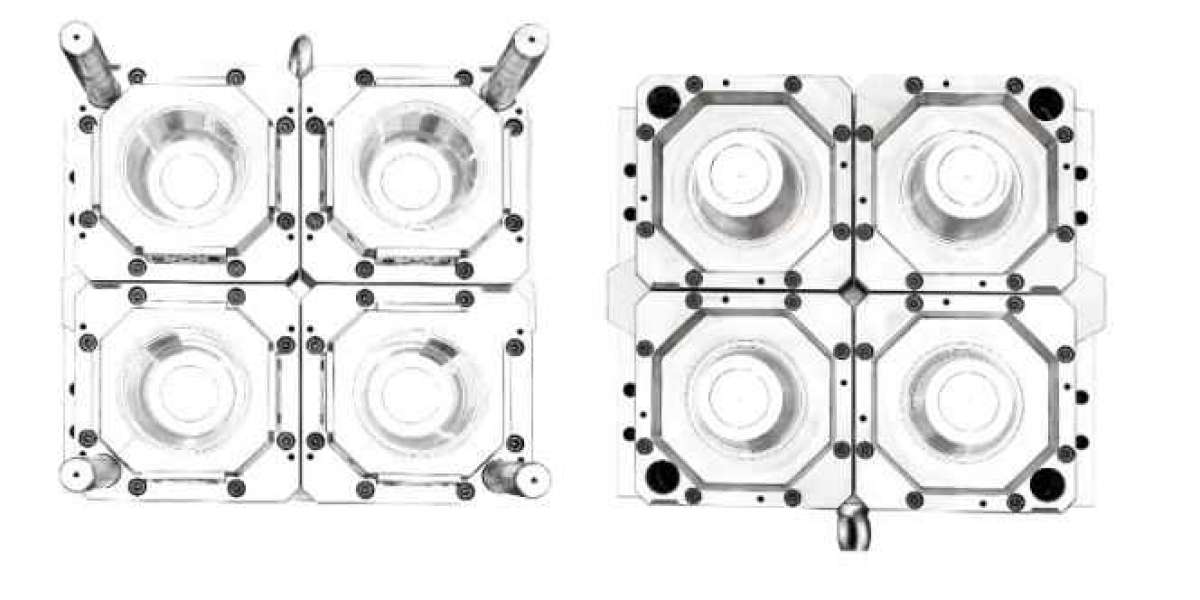

Additionally, the physical size and weight of the servo motor should be taken into account, especially in applications with limited space or weight restrictions. Low voltage servo motors are available in a range of sizes and configurations, allowing for flexibility in design and integration.

The compatibility of the servo motor with existing control systems and communication protocols is another important consideration. Ensuring seamless integration with the control system will facilitate smooth operation and system functionality.

Furthermore, factors such as environmental conditions, duty cycle, and maintenance requirements should be evaluated when selecting a low voltage servo motor. Choosing a motor with robust construction and suitable protection against dust, moisture, and other contaminants will enhance reliability and longevity, especially in harsh operating environments.

In summary, low voltage servo motors offer numerous advantages, including energy efficiency, performance, and versatility, making them a preferred choice for many industrial and automation applications. When selecting a low voltage servo motor, careful consideration of factors such as power requirements, physical size, compatibility, and environmental conditions is essential to ensure optimal performance and reliability. With the right selection and integration, low voltage servo motors can contribute to the efficiency, productivity, and sustainability of various systems and processes.